The efficient cleaning of metalworking machines is essential for maintaining product quality and minimizing machine downtime. With its Microsolv NX cleaner, Eco-nova offers an innovative solution that has been specially developed for use in the metalworking industry. This practical example shows how a customer was able to optimize its cleaning processes and reduce its environmental impact at the same time by introducing Microsolv NX.

Removal of polyol and isocyanate from aluminum molds

Successful launch of our Nova Safe S solvent for cleaning aluminum molds that are contaminated by polyols and isocyanates, among other things, during the production process.

Removal of oil-wax-rubber deposits with RF Cleaner

A customer who produces additives for the plastics industry approached us with the requirement to find a safe industrial cleaner to effectively dissolve the oil-wax-rubber deposits in their production area. With RF Cleaner, we recommended a safe solvent that proved to be a suitable solution.

Cleaning silicone residue on PU rollers, machines and floors

The customer has problems with silicone deposits in the entire production area. These are deposited on PU rollers, machines, floors and equipment. Cleaning is currently proving to be unsafe for people and the environment, as the solvents used contain VOCs and hazardous substances.

Cleaning of silicone binder rollers in the production process of glass fiber wallpapers

We supported our customer in the cleaning of silicone binder rollers in the production process of glass fiber wallpaper. By using our industrial cleaners, the time and effort required for the cleaning process was significantly reduced.

Eco-Nova is committed to German-Dutch exchange

Why is the German-Dutch exchange important?

More than five thousand Dutch companies have branches in Germany, where the demand for German-speaking Dutch nationals is high. But German companies on the other side of the border, in Germany itself, are also looking for Dutch nationals to fill their vacancies. A good knowledge of German makes applicants six times more attractive on the job market. Unfortunately, these career opportunities are often underestimated and the importance of the German language only really becomes apparent later in professional life, especially in the border region.

Politicians also supported German-Dutch cooperation

The German-Dutch Chamber of Commerce (DNHK) emphasizes the special importance of the German language in the border region, where trade between the two countries is visible on many levels. Cross-border cooperation in culture and politics is also highlighted as valuable. Missing out on opportunities due to a lack of German language skills is seen as particularly regrettable.

Eco-Nova's contribution to understanding in the border region

Today #RudideLeeuw from #econova taught two 2 secondary school classes at #bonhoeffercollegeessinkweg about the importance of learning German language and culture in the Twente region. He shared his experiences from 31 years of entrepreneurship in Germany. He has been an entrepreneur with his company in Schüttorf, Lower Saxony, since 1993. He particularly emphasized the value of the German language and culture in the working world. The students had the opportunity to ask questions, which led to an educational afternoon. This initiative was co-organized by #duitswerkt and German teacher Nardy Tiehuis. Rudi, who has been speaking German daily for more than 30 years, shared his views and experiences on the crucial importance of the German language for young people in the border region, where trade, cooperation and opportunities are tangible on many levels. He also emphasized that knowledge of German also provides the opportunity to find a good job just across the border in Germany.

Health-conscious cleaning in industrial companies: Why avoiding VOCs is crucial

In industrial cleaning, efficiency and performance are key factors. But while companies often rely on high-performance cleaners, it is often overlooked that many of these products can contain volatile organic compounds (VOCs), which can affect not only the health of employees, but also the environment.

VOCs in industrial cleaning: The underestimated danger

- Employee health: Industrial cleaning products containing VOCs can lead to poor indoor air quality. Long-term exposure can lead to respiratory problems, headaches and other health complaints among employees.

- Environmental impact: The release of VOCs contributes to air pollution and, in combination with other industrial emissions, can lead to significant environmental impacts.

- Regulatory requirements: More and more countries are tightening their environmental regulations and setting limits for VOC emissions. Companies that do not switch to environmentally friendly cleaning agents risk legal consequences and fines.

The solution: VOC-free cleaners for industry

- Effectiveness without compromise: Modern VOC-free industrial cleaners are just as powerful as their conventional counterparts. Advanced formulas provide thorough cleaning without harmful side effects.

- Occupational safety: VOC-free cleaning agents help to improve working conditions and minimize the risk of health complaints among employees. Healthy employees are more productive and contribute to a positive working environment.

- Environmental friendliness: Companies that switch to VOC-free cleaning agents are demonstrating an environmentally conscious commitment. This can not only strengthen the company's image, but also help to meet regulatory requirements and avoid potential penalties.

Conclusion: Sustainable cleaning for sustainable success

Industrial companies face the challenge of finding high-performance cleaning solutions that simultaneously respect the health of employees and minimize environmental impact. Switching to VOC-free cleaning products is not only an ethical decision, but also a strategic investment in the future of the company. It's time for the industry to rethink its cleaning practices and pave the way for a healthier, more sustainable future.

Sustainable cleaning in the industry: why it is important to avoid hazardous substances

A clean production process is not only crucial for the quality of the end products, but also for the safety and health of employees and environmental protection. In industrial cleaning, however, many cleaning agents are associated with hazardous substances that can pose considerable risks to people and the environment. This blog post looks at the reasons for avoiding hazardous substances in industrial cleaning and why switching to safe cleaners is a sustainable choice.

1. protect the health of employees

A key aspect in the selection of cleaning agents is the health of employees. Many conventional cleaning agents contain hazardous chemicals that can cause respiratory problems, skin irritation and other health problems. The use of safe cleaners minimizes the risk of damage to health and creates a safe working environment.

2. CLP labeling and transparency

The CLP Regulation (Classification, Labeling and Packaging) lays down uniform rules for the classification, labeling and packaging of chemicals throughout Europe. Hazardous substances are often labeled with hazard symbols and H and P phrases. Switching to safe cleaners often means using products with minimal or no CLP labeling, resulting in greater safety. In addition, you often save on the purchase of expensive storage equipment. Fire protection, personal protective equipment or other mandatory storage items are no longer needed if you do without hazardous substances.

3. environmental protection due to low VOC content

Volatile organic compounds (VOCs) are volatile organic compounds that can not only impair indoor air quality, but also contribute to the formation of ground-level ozone and thus to environmental damage. Many conventional cleaning agents contain high levels of VOCs. By using environmentally friendly cleaners with a low VOC content, companies can actively contribute to environmental protection.

4. sustainability and corporate social responsibility

In the age of sustainability and corporate social responsibility (CSR), it is important for companies to minimize their environmental impact. Switching to safe cleaning products is a step in the right direction to take ecological responsibility and improve your own sustainability footprint.

5 Effectiveness and efficiency

Modern safe cleaning products are often just as effective as their hazardous alternatives without endangering the health of employees or the environment. In the long term, companies can benefit from a lower sickness rate, an improved working atmosphere and a positive image, which will ultimately lead to an increase in profitability.

Conclusion

Avoiding the use of hazardous substances in industrial cleaning is not only a protective mechanism for employees, but also a contribution to environmental protection and sustainability. Companies that switch to safe cleaning agents not only demonstrate social responsibility, but can also benefit in the long term from the positive effects on health, the environment and profitability. A conscious choice of cleaning agents therefore makes a significant contribution to creating a safe, healthy and sustainable working environment in industry.

Masterbatch mixing vessel cleaning with Microsolv

Introduction of the industrial cleaning concentrate Microsolv as a replacement for hazardous cleaning chemicals in masterbatch mixing vessel cleaning.

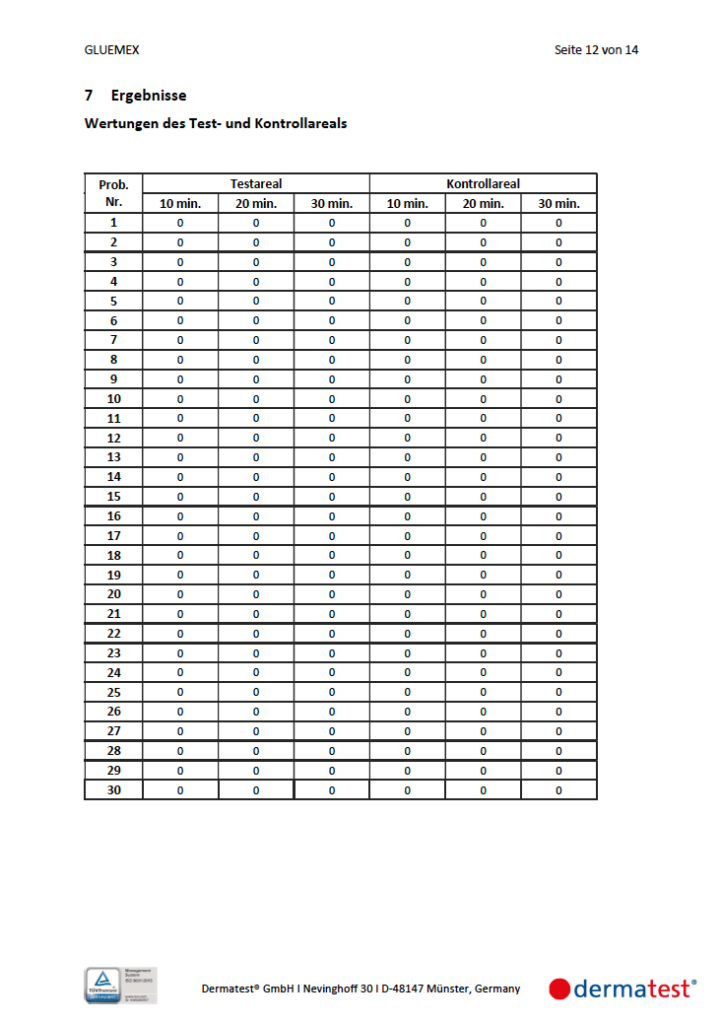

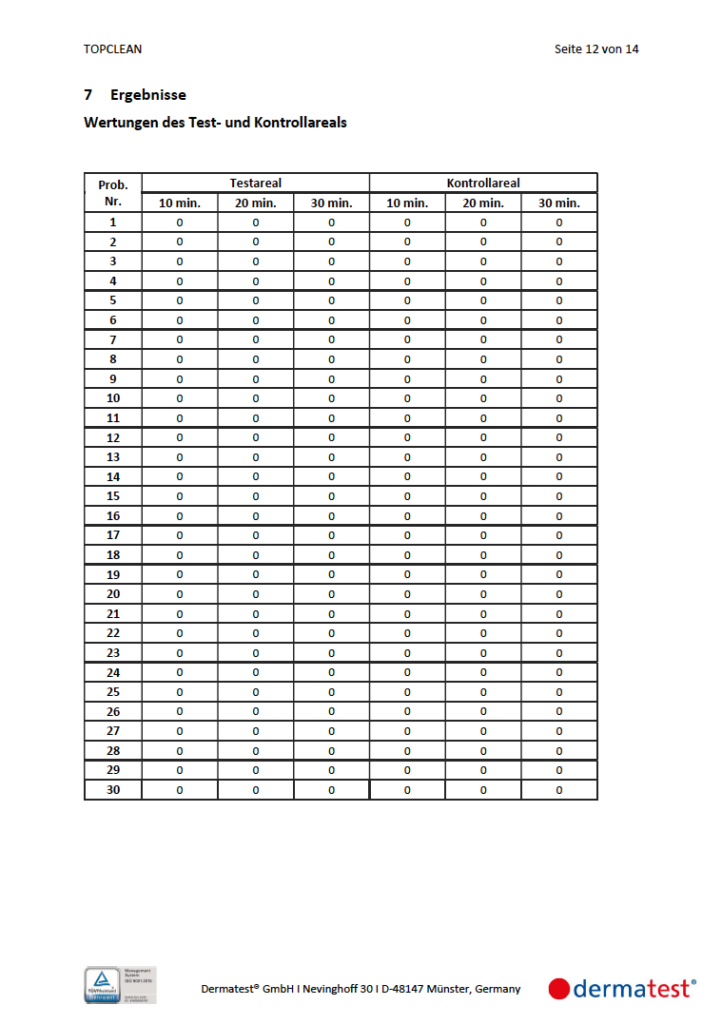

Dermatest - Gluemex and Topclean successfully tested for skin compatibility

Our industrial solvents without hazardous substances have been independently tested for skin compatibility by DERMATEST. Topclean and Gluemex were rated as "very good". We are therefore now allowed to use the seal with the skin compatibility rating "very good" on our cleaners.

The test was carried out on test subjects who were selected according to strict Dermatest test guidelines. The result shows that cleaning with our solvents Topclean and Gluemex is safe for the skin of your employees and colleagues.

Would you like to find out more about Dermatest? Then please visit the Dermatest website at http://www.dermatest.de

You can see the detailed test results for Topclean and Gluemex in the following pictures.

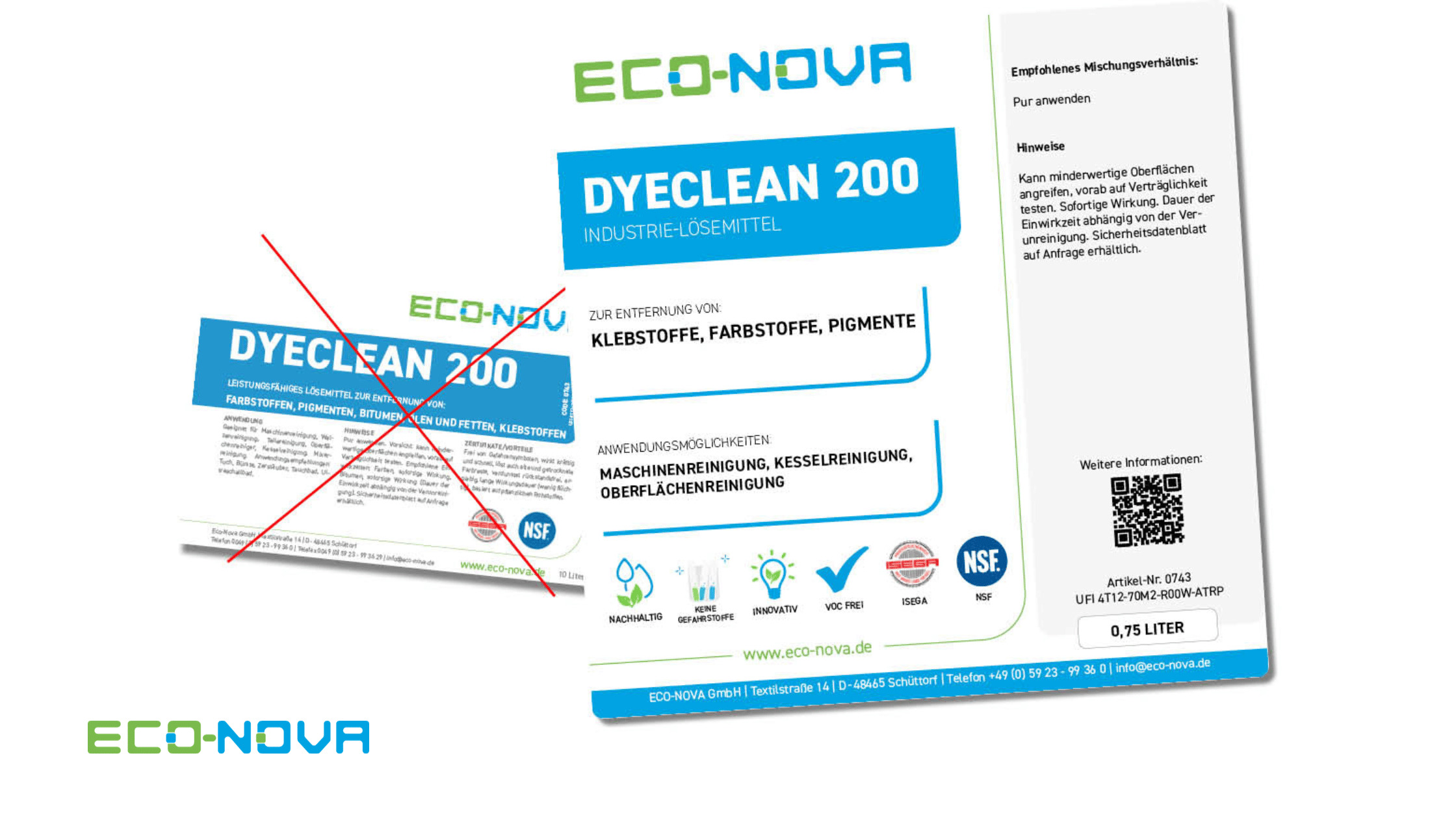

Our new labels - This changes

Since November 1, our cleaners have been shipped with new labels. The new labels have been adapted to the current requirements of our customers. The changes include a new clear design, a more compact layout and the placement of the most important properties in prominent positions so that the most important information about our cleaners can be found without having to search for a long time.

These are the most important changes in detail:

New format

Our old labels were in 2:1 format. The format was not compatible with small containers under 20 liters. Our new labels are now square. This allows us to label significantly more containers with a uniform format, which means that users can always find the information in the same place on the label, regardless of the container size.

New seals & symbols

Our new seals & symbols help to quickly identify which properties and certifications the cleaner fulfills. In addition to test seals, e.g. from ISEGA or NSF for food safety, our ECO-NOVA seals for sustainability, VOC content & more are also placed on the labels. Further information on our ECO-NOVA seals can be found under Industrial cleaners

Important contents

It was particularly important for us to place the most important information prominently. So we asked ourselves, what questions do you ask when using an industrial cleaner? Our answers were: What kind of soiling do I want to clean and with which process or from which surface do I want to remove it. These two pieces of information are therefore prominently displayed on the new labels.

Notes

In addition to the legally required information, we provide additional instructions for the use of our cleaners. All instructions are listed in a separate area on the right-hand side of the label so that they can be found quickly and easily.

Anilox roll cleaning with Novaflex

ECO-NOVA was commissioned to optimize the cleaning of the in-house anilox rollers, as the current cleaner did not achieve sufficient cleaning results and had several hazard pictograms. In addition to better cleaning performance, the new cleaner should contain as few or no hazardous substances as possible.

Ink removal on continuous inkjet systems and coding production lines

Coding has become an indispensable part of our everyday lives. It now touches all areas of life and all industries.

Continuous Inkjet Systems: Continuous Inkjet Systems (CIJ) are widely used in industry. These printers spray ink through a nozzle outlet to create markings on products. They are especially useful in production lines where codes or other information must be printed on fast or continuous belts. They are very versatile and can print on a wide variety of materials and surfaces.

Coding production line: In a production line, coding is very important. It refers to putting barcodes, QR codes, dates, lot numbers or other relevant information on the products. These codes can be used for a variety of purposes, such as inventory, tracking, quality control, etc.

Now to the specific industries you mentioned:

Food and confectionery: In these industries, accurate coding is critical to ensure consumers receive important information such as expiration dates, ingredient lists and nutritional information.

cosmetics and pharmaceuticals: In these industries, coding is particularly important for traceability and ensuring product quality. Coding allows pharmaceutical companies to monitor the batch of a particular drug and ensure that product quality and safety are guaranteed.

Cables and pipes: This industry often uses some kind of permanent marking for cables and pipes to indicate important information such as manufacturing date, type, specifications and safety certifications.

Beverage and Dairy Industries: These industries require strict coding and marking to ensure compliance with food safety standards. In addition, these codes help manage the production process and perform product recalls when necessary.

In all these applications, continuous inkjet systems and other industrial printing systems can play a key role in effectively coding products on the production line.

Eco-Nova has a selection of cleaning products for ink removal, including Microsolv NX, Plexinova and Topclean. These products provide a safe solution to your cleaning needs that is not only effective, but also environmentally friendly. Eco-Nova products are hazardous material and label free.

Eco-Nova's ink removal product range offers you the solution for your cleaning tasks.

Effective steel mold cleaning without hazardous substances

If possible, the customer's metal molds should be cleaned with cleaners that are free of hazardous substances. The final cleaning should also be as residue-free as possible. The use of particularly volatile solvents, which flash off quickly, was prohibited by the company because they are too dangerous for the employees.

Removing permanent marker

Remove and clean paint marker, permanent marker and gloss paint marker ( Edding pencils ) when drawing, writing and marking on smooth and dark surfaces such as metal, plastic, tires, glass, wood, stone and many other surfaces.

Various adhesives in the industry

Various adhesives in the industry.

Today, adhesive bonding technology is regarded as the innovative joining technology of the 21st century, and the companies of the German adhesives industry - also in the international competitive environment - as technology leaders. Adhesive bonding technology makes significant contributions to the development of innovative products and provides the industry with the prerequisites for opening up new, future-oriented markets in all sectors.

In the early 1980s, polymer chemists from the adhesives industry worked together with engineers from the automotive industry for the first time in a publicly funded research project to successfully develop a process for bonding oiled sheet metal in automotive production and introduce it in a process-safe manner.

This successful interdisciplinary interaction between chemistry and engineering initiated further projects, systematic research and development. When an accredited personnel qualification system for adhesive processors and manufacturers was introduced in the early 1990s, all the necessary conditions were in place to put the adhesive industry on the road to success as an innovative system partner. The use of adhesive technologies enables small and medium-sized companies to face their competition by creating innovative products.

What are the different types of adhesives?

Here is a selection of adhesives used in the industry:

- Epoxy adhesives: With their impressive strength and resistance to chemicals and temperatures, epoxy adhesives are ideal for demanding industrial applications. They provide a reliable bond for metal joints and are perfect for construction projects where high strength is required.

- Polyurethane adhesives: Versatile and flexible, polyurethane adhesives are ideal for a wide range of substrates such as metal, plastic, glass and wood. Not only do they provide strong adhesion, but they are also impact resistant and ensure a long-lasting bond.

- Acrylic Adhesives: When you need fast cure time, high strength and weather resistance, acrylic adhesives are the right choice. These adhesives are ideal for use in the automotive and construction industries, where a reliable bond is required under extreme conditions.

- Cyanoacrylate adhesives: For quick repairs and bonding, cyanoacrylate adhesives, also known as instant adhesives, are unbeatable. Their fast cure time and strong adhesion make them ideal for everyday use and small repair jobs.

- Silicone adhesives: Silicone adhesives offer flexibility, temperature resistance and excellent adhesion to a wide range of surfaces. They are the perfect solution when a flexible bond or reliable seal is required.

- Hotmelt adhesives: Hotmelt adhesives, also known as hot melt adhesives, allow you to bond materials together quickly and strongly. These adhesives melt when heated and provide a quick solution for various applications.

The industrial adhesives mentioned above are only a selection from the wide range of available adhesives. Depending on specific requirements, there are also specialized adhesives such as metal adhesives, structural adhesives for aircraft construction or conductive adhesives for the electronics industry. When selecting the right adhesive, it is important to consider the requirements of the specific application.

In order to successfully exploit the advantages of adhesive bonding technology compared to other joining processes, the entire process from product planning to quality assurance and employee qualification must be implemented properly. However, this can only be achieved if research and industry work closely together so that the research results can be rapidly and directly incorporated into the development of innovative products and production processes.

One of the tasks of the Industrieverband Klebstoffe e.V. (Adhesives Industry Association) is to promote this development in order to increase the use of adhesive bonding technology in all areas. As a member of the board of the DECHEMA specialist group "Adhesive Bonding Technology" and the "GAK" (Joint Committee on Adhesive Bonding), the Adhesives Industry Association accompanies the coordination of publicly funded research projects in the field of adhesive bonding technology.

The potential of the adhesives industry has not been exhausted either technologically or in terms of the market. Clear growth opportunities can be seen for the future - be it in the direction of redetachable adhesive bonds or the assumption by adhesives of functions previously performed by other materials.

Eco-Nova has developed various cleaning products without hazardous substances (not subject to labeling) to remove the adhesive residues:

Dyeclean 200, Gluemex, Topclean and Microsolv NX. Please contact the technical consulting team.

Removal and cleaning of asphalt on construction machines

Maintenance and cleaning of construction machinery is an essential part of the operations in the asphalt industry and construction industry. Cleaning asphalt often presents a challenge to companies.

Machines, which are often contaminated with tar or bitumen, often include:

- Crawler excavator

- Motorgrader

- Road rollers

- Asphalt mixing plants

- Wheel loader

- Asphalt paving machines

- Road grader

- Shuttlebuggies

The contaminants on the machines can cause the efficiency to be reduced, the wear to increase or the contaminants to cause corrosion. ECO-NOVA offers a range of safe and effective release agents and solvents, such as Antistik 100, Bitunova NF, Bituclean and Combisolv TR.

How important is regular cleaning of construction machinery

Regardless of the type of machine - whether it is a motor grader for grading and profiling, a road roller for compacting asphalt, or an asphalt mixing plant - each of these machines should be cleaned and maintained regularly to ensure proper operation.

ECO-NOVA cleaning concentrates and release agents

ECO-NOVA offers a range of safe cleaning concentrates and solvents specially developed for the effective removal of asphalt and bitumen residues on a variety of machines. Antistick 100 is a release agent or non-stick agent that reduces the adhesion of asphalt to machines such as crawler excavators, motor graders and road rollers. It forms a protective layer that prevents asphalt from sticking and makes cleaning easier. In practice, diesel is still often used as a release agent. However, diesel is a highly environmentally hazardous substance and should therefore no longer be used. With Antistick 100, we offer a much safer release agent. The solvent Bituclean solvent is also used to safely and effectively remove stubborn bitumen residues from machines such as asphalt mixing plants, asphalting machines and road graders. Combisolv TR is a versatile cleaner that can remove both asphalt and bitumen, ideal for machines such as shuttle buggies and wheel loaders.

Anti-stick solutions for trucks

Transporting asphalt by truck in the asphalt industry is often challenging: Asphalt sticks to the truck beds. This can make unloading difficult and result in unnecessary material waste. In addition, cleaning up this sticky residue can be time-consuming and difficult. ECO-NOVA offers with Antistick 100 an effective anti-adhesive specifically designed to reduce the adhesion of asphalt to surfaces. If Antistick 100 is applied to truck bed surfaces, it forms a barrier between the asphalt and the surface of the truck. This prevents the asphalt from sticking to the truck, allowing for smoother unloading and significantly reducing cleanup time. Through the use of Antistick 100 companies in the asphalt industry can not only make their operations more efficient, but also extend the life of their trucks and reduce the need for too frequent, thorough cleaning.

Technical support and customer service

If you need comprehensive technical support or have questions about the use of these products on specific machines, please contact our technical consulting team. We will be happy to assist you with any questions you may have.

In practice

Many companies already benefit from the advantages of ECO-NOVA cleaning solutions. Cleaning processes are improved, employee safety is increased and, at the same time, environmental awareness is increased. Positive experiences and feedback from the field confirm the effectiveness and reliability of ECO-NOVA cleaners. Thanks to ECO-NOVA cleaners, construction machinery, road pavers, asphalting machines, etc. can be cleaned safely and effectively without having to resort to hazardous chemicals.

Cleaning adhesives

Cleaning adhesives can be a difficult task.

Different types of adhesives require different methods and solvents for effective removal. Adhesives can leave stubborn residues on surfaces such as glass, metal, plastic or fabric that are unsightly. Functionalities can be compromised as a result. Below are some common methods and tips for cleaning adhesives:

Determine the type of adhesive: Before attempting to clean the adhesive, determine the type of adhesive used. Common adhesives include:

- Two-component construction adhesives

- One-component construction adhesives

- Hotmelt adhesives or hotmelt

- Reactive PUR hotmelt adhesives (polyurethane-reactive)

- Solvent- and water-based adhesives

Different adhesives may require different cleaning methods

Heat: Certain adhesives can be softened by heat, making them easier to remove. You can use a hair dryer or heat gun on a low setting to heat the adhesive. Once the adhesive is softened, carefully scrape it off with a plastic scraper. Be careful not to damage the surface.

Scraping tools: For more stubborn adhesives, you may need to resort to scraping tools. Plastic scrapers as well as cloths can be used to gently scrape or clean off the adhesive. Be careful not to scratch or damage the surface.

Solvents: There are many adhesive removers and solvents available on the market that have been specially developed for dissolving and removing adhesives. However, these are mostly subject to labeling and contain hazardous substances such as isopropanol, acetone or ethylene glycol. In ECO-NOVA's portfolio you will find safe adhesive removers that do NOT require labeling and are free of hazardous substances, such as Gluemex, Topclean or Dyeclean 200.

Always remember to test a solvent first on a small and inconspicuous area to ensure it will not damage or discolor the surface. Remember to always read the instructions when using ECO-NOVA cleaners or adhesive removers. Consider the surface condition to avoid damage to the material.

Interview with Easy Engineering Magazine

In an interview with Easy Engineering, Rudi de Leeuw, Managing Director of ECO-NOVA GmbH, talks about trends in the market and innovative products.

ECO-NOVA listens to customers' questions and problems, responds immediately and finds real solutions. The company sets itself high standards in terms of quality and responsibility. This makes them pioneers in product strategy in Europe and worldwide. Easy Engineering spoke with Rudi de Leeuw.

Easy Engineering: Briefly describe your company.

Rudi de Leeuw: This year, ECO-NOVA GmbH looks back on more than 30 years of company history. At our site in Schüttorf, in Lower Saxony near the Dutch North Rhine-Westphalian border, we develop and produce innovative cleaners for industrial customers. Our ambition is to develop safe cleaning solutions that are free of hazardous substances and yet highly effective. We are not a chemist in the classical sense, but rather developers in the field of sustainable cleaners for industry.

In our production, we fill cleaners in ready-to-use containers of up to 1,000 liters. We help our customers solve cleaning problems and are often part of the production process. Our core competence includes the recording of individual cleaning requirements and the development of a solution in close and personal consultation with our customers. On the way to solving a cleaning problem, we rely on existing cleaners and on the development of customer-specific formulations. We constantly adapt our cleaners to the needs of the market and our customers. Our claim is always to do without hazardous ingredients or to reduce them to a minimum.

E.E: What are the main areas of activity of the company?

R.d.L: We supply our cleaning solutions to large industrial and commercial customers throughout Europe, and will act in an advisory capacity right through to the development and production of a customized solution. In the development of new cleaners we succeed in replacing established but labelled cleaners with innovative cleaners based on natural or safe raw materials.

E.E: What's new with the products?

R.d.L: What is new for us is not the product, but the process for solving a customer challenge. We rely on existing recipes and formulas as well as on completely new product developments. Our products define themselves as new in that they solve cleaning problems that our customers have never had before. Similarly, it sometimes leads to the removal of an age-old problem with a cleaning solution that is already in our portfolio. We develop new products in close cooperation with our customers and suppliers.

E.E: What are the product ranges?

R.d.L: The application areas for our products are very diverse. In the development of our cleaners, we rely on safe and natural raw materials that provide excellent cleaning performance for the corresponding application areas. Our range includes solutions for many different types of industrial soiling. We have developed our cleaners for industries such as the chemical and raw materials industry or from the field of plastic and metal prefabricated parts. Likewise, our cleaners are used in the packaging and food industry and we remove bituminous contaminants, tea or asphalt in road construction, mixing plants or industrial product plants. Our experience in the various industries helps us to replace already established but labelled cleaners with innovative cleaning solutions that contain no or only a few hazardous substances. Many of our cleaners are based on natural and safe raw materials. Many of our products are ISEGA or NSF certified.

Switching to our cleaners usually not only improves occupational safety for employees, but also reduces the environmental impact due to fewer pollutants. In addition, a large proportion of our cleaners have no or very few VOC substances.

E.E: At what stage is the market you are currently operating in?

R.d.L: The market has been in continuous motion for over 30 years. For example, laws and regulations regarding the handling of cleaners or their ingredients change fundamentally. The industry is looking for sustainable and safe cleaning solutions and the demand is increasing. The competition is pushing into the market with a multitude of cleaners for a wide range of applications. However, we always try to look ahead and be one step faster than others. We focus on a compact company size and our functional teams work very closely with our customers. This way we guarantee a very fast service and can respond within 24 hours.

The demand in the market for safe and effective cleaners is increasing. We take advantage of market conditions and have positioned ourselves where customers looking for solutions for their processes find us as consultants, developers and producers.

E.E: What can you tell us about the market trends?

R.d.L: Checking the cleaning results as well as the cleaning processes has a very high priority in production and trade. It is therefore not surprising that many companies are looking for improved, ecological and symbol-free cleaners. We are experiencing strong demand in the area of symbol-free clean ers and strongly expect this trend to continue in the coming years.

E.E: What are the most innovative products being marketed?

R.d.L: Many industrial applications use cleaners that contain hazardous substances and therefore pose a challenge for safe and environmentally conscious work. Our products do not contain

hazardous substances and at the same time have an enormously high cleaning effect. From our point of view, this is already an innovation.

In addition, our products are used in industries that at first suggest that the impurities prevailing there can only be cleaned with "sharp substances". However, our cleaners have excellent cleaning properties for bituminous or asphalt contamination, are highly effective in cleaning polymer cracking in the masterbatch industry or dissolve dyes and pigments in the printing sector or roller cleaning. ECO-NOVA cleaners are certified for the food industry by ISEGA and NSF. The industrial application areas are very diverse and our cleaners are often a novelty when our customers use them for the first time.

E.E: What are your estimates for 2023?

R.d.L: For 2023, we expect further growth of our company. We have restructured ourselves in the area of consulting, so that our customers are supported in all questions in the newly established functional teams. This is our response to the changes in the market and we expect that our customers will benefit greatly from the restructuring and that we will work closely together.

Cleaning rollers in industry

There are several methods to clean rollers in the industry.

Acetone is often used to remove various dirt, cracks and contaminants. However, this can become dangerous and cause health problems if the solvent is not used properly and carefully.

Acetone is a commonly used cleaning agent in industry. This solvent contains the H-phrase "H314" which contains warnings of harmful effects on the respiratory tract and skin. To reduce or avoid these risks, companies should use cleaners without acetone. One of the most common alternatives to acetone is methanol. Like acetone, methanol also contains hazard symbols such as the hazardous substance pictogram GHS 05 for skin irritation (corrosive), but it has a less toxic effect on the skin and respiratory tract. In addition, it should be noted that methanol is toxic if drunk, so appropriate precautions should be taken.

Many substances are not harmless

Another substance that is used instead of acetone is ethylene glycol. This cleaning agent contains hazard symbols such as the exclamation mark (GHS07) and the hazard statement "H315 - Causes skin irritation". This ingredient has a less toxic effect on the skin and respiratory tract than acetone or methanol. In addition, ethylene glycol is not toxic when drunk. However, it should be noted that it is corrosive, so appropriate precautions should be taken. Another option that is often used for roller cleaning in industry is isopropanol (IPA). This substance also contains hazard symbols, but it has a less toxic effect on the skin and respiratory tract than acetone or other alternative products. Isopropanol is also non-toxic when drunk. It is also corrosive, but not as corrosive as ethylene glycol.

Acetone, ethylene glycol or isopropanol, these materials or ingredients are not harmless and can lead to various negative scenarios.

Safe cleaning without hazardous ingredients

Industrial companies looking for a safe and effective method of cleaning rollers will find the use of ECO-NOVA cleaners a viable solution without having to use cleaning agents containing hazardous materials. This type of symbol-free cleaner offers several tremendous advantages over traditional acetone or similar-based products. One of the biggest advantages is safety. Acetone, for example, contains toxic substances that can be harmful to human health if used improperly. It can also cause severe explosions if it comes into contact with other chemicals. Therefore, when handling acetone-based cleaners, companies must follow strict safety rules.

However, with ECO-NOVA cleaning solutions that do not contain hazardous substances, companies can ensure that their employees will not suffer any damage to their health if used correctly or that the cleaners could cause explosions.

In addition, we achieve excellent cleaning results with our modern and safe products.